The workforce believes its chitosan formulation may be slotted proper into presently obtainable equipment for producing polyurethane or PVA (that plastic movie utilized in laundry pods), so manufacturing of shrimp-leather items may very well be scaled up shortly. Now TômTex is shifting operations from a small lab in Newlab to a bigger pilot manufacturing house a brief stroll away within the Navy Yard, the place the corporate can hopefully show its thesis. The cofounders walked me over to see it, however the facility was only a suggestion of what it may very well be. They have been nonetheless ready for {the electrical} to be put in, and all of the lab gear was plugged into one overworked extension twine.

The small setup in the course of the room seemed like a mixture of a bakery and a lab, with superior technical gear, a commercial-grade meals dryer, and cabinets piled with beakers and cookie sheets. The air smelled ever-so-slightly candy, possible as a result of chitosan, a polysaccharide, is became one thing that appears like molasses throughout the manufacturing course of. (And no, there’s no shellfish odor.)

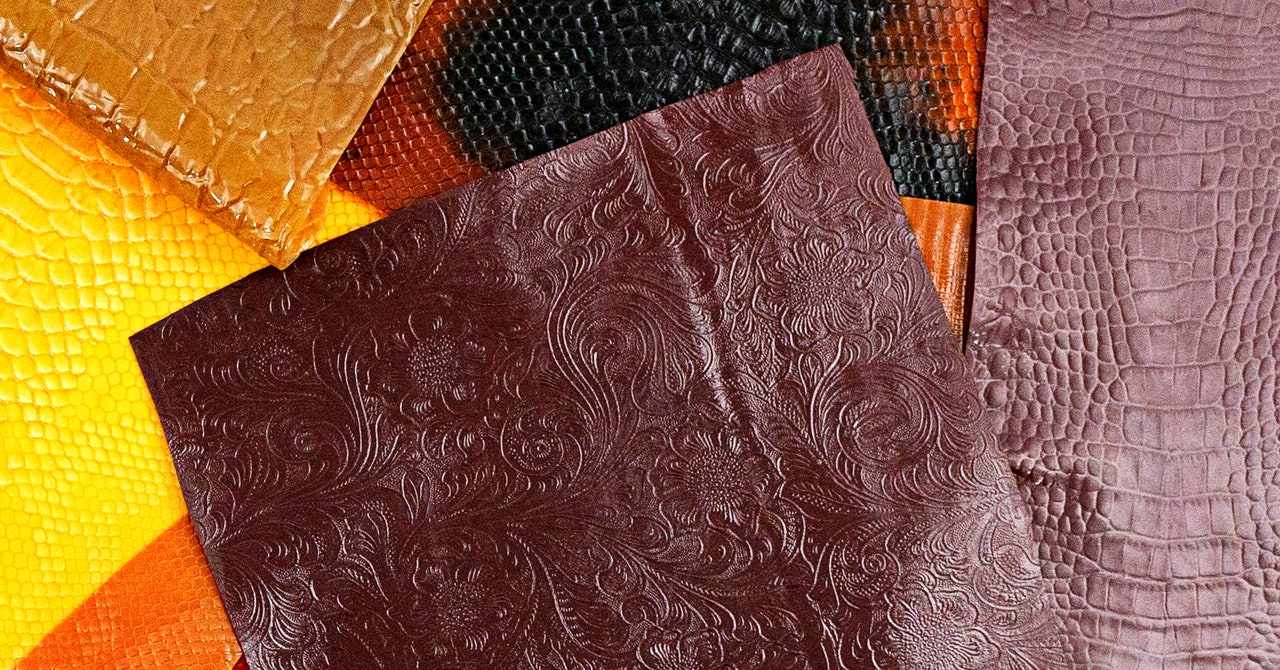

A development bucket of jaggedly minimize outdated materials samples in a rainbow of colours and textures sat on the ground. McBee stated they’ve melted down outdated samples and made them into new samples. In some instances, the chitosan leather-based has been melted down and reconstituted twice, which is twice greater than most different vegan leathers. “I don’t wish to promise that the very, very closing model of this shall be this, as a result of this adjustments relying on the sure chemistry,” he stated. “However for the time being, the recipe is one thing the place you possibly can take a closing sheet and mainly soften it again down.”

That’s music to the ears of the style trade, which has been talking up the distant utopia of a circular economy, the place used clothes and accessories are endlessly looped by way of the availability chain to create new merchandise. It wasn’t till a few months in the past, when the TômTex workforce discovered the way to make the fabric waterproof, that they’d the boldness to begin sharing the leather-based substitute with bigger manufacturers and the press. TômTex is now in talks with a big leather-based items model, an athletic put on model, and a sneaker model to begin utilizing its materials in mass-market merchandise. Behind the desk with the 3D printer, a whiteboard listed a few of the world’s largest trend companies with manufacturing portions subsequent to them.

Getting a dedication from these manufacturers to purchase a certain quantity of product shall be key, says Nunes. “The kind of factor that traders love to listen to is sure, we’re getting commitments, and all these corporations and types are very . That’s when the traders will put money into the cash, after which get them the power they want so as to produce the capability that they want to have the ability to serve these manufacturers.”

TômTex hopes to be producing its leather-based substitute on the dimensions of 100,000 yards a yr by the top of 2023, which is a lightning-fast timeline in comparison with lots of the different trend materials improvements which were in growth for a decade or extra. “We’re hopeful that inside this yr, there’ll be one thing that individuals can truly get their arms on,” McBee stated.

That could be optimistic, and can rely upon how profitable TômTex is on this fundraising spherical and the attendant expertise refinement stage. Gladman at MII says the institute expects a slowdown and consolidation within the leather-based different market this yr, which has dozens of entrants who’ve been chugging alongside for nearly a decade with little in the way in which of shopper merchandise to indicate for it.

“We predict some startups would possibly fail,” Gladman says. “And it’s a little bit unhappy, however on the identical time, it’s an indication of progress within the trade.”

If it retains going at this tempo, TômTex would possibly find yourself coming from behind to win.